Add to Cart

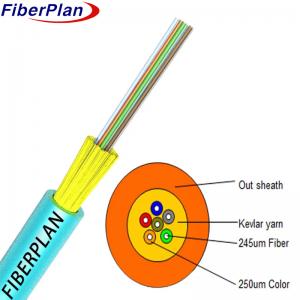

Mini Bare Kevlar Strengthen Fiber Distribution Fiber Optic Cable

Description

The break-out indoor cable is constructed using simplex cables as subunits. In the center of the core, a non-

metallic strength member made of Fiber Reinforced Plastic (FRP) provides structural support. The subunits

are stranded around this central core. To enhance protection and safety, the cable is finished with a jacket

made of either PVC or LSZH (Low Smoke, Zero Halogen, Flame-retardant) material. This design ensures

durability, flexibility, and compliance with safety standards for indoor applications.

Application

1 Indoor Cabling, Breakout Applications: Specifically designed for indoor cabling, this cable is well-suited for

breakout scenarios, providing reliable connectivity within buildings.

2 Pigtail for Communication Equipment: Functions seamlessly as a pigtail for communication equipment,

ensuring efficient and dependable connections.

3 Compatibility with Communication Equipment: Tailored to meet the requirements of communication equipment,

ensuring suitability and effective service.

4 All-Purpose Mini Indoor Cable: Versatile and compact, serving as an all-purpose mini indoor cable suitable

for various communication needs.

5 MPO, MTP Connector Compatibility: Designed to work seamlessly with MPO and MTP connectors, offering

flexibility and compatibility with different connector types.

Characteristics

1 Ideal for indoor distribution, suitable for creating patch cords and pigtails.

2 Features a multi-cable design with independent strength members.

3 Utilizes a non-metal central strength member for durability.

4 Enhanced strength with high-strength Kevlar yarn member.

Cable Mechanical characteristic

| Items | Cable diameter | Weight | |||||

| 24 cores | 10 | 54.00kg/km | |||||

| 48 cores | 10 | 78.00kg/km | |||||

| 72 cores | 11.5 | 90.00kg/km | |||||

| 96 cores | 12.5 | 115.00kg/km | |||||

| 144 cores | 14.5 | 135.00kg/km | |||||

| Storage temperature(℃) | -20 ~ +60 | ||||||

| Min Bending Radius(mm) | Long term | 10D | |||||

| Min Bending Radius(mm) | Short term | 20D | |||||

| Min allowable Tensile Strength(N) | Long term | 1000 | |||||

| Min allowable Tensile Strength(N) | Short term | 2000 | |||||

| Crush Load (N/100mm) | Long term | 1000 | |||||

| Crush Load (N/100mm) | short term | 2000 | |||||

Fiber characteristic

| Fiber style | Unit | SM G652 |

SM G652D |

MM 50/125 |

MM 62.5/125 |

MM OM3-300 |

|

| condition | nm | 1310/1550 | 1310/1550 | 850/1300 | 850/1300 | 850/1300 | |

| attenuation | dB/km | ≤ | ≤ | ≤ | ≤3.0/1.0 | ≤3.0/1.0 | |

| 0.36/0.23 | 0.34/0.22 | 3.0/1.0 | ---- | ---- | |||

| Dispresion | 1550nm | Ps/(nm*km) | ---- | ≤18 | ---- | ---- | Dispresion |

| 1625nm | Ps/(nm*km) | ---- | ≤22 | ---- | ---- | ||

| Bandwith | 850nm | MHZ.KM | ---- | ---- | ≧400 | ≧160 | Bandwith |

| 1300nm | MHZ.KM | ---- | ---- | ≧800 | ≧500 | ||

| Zero dispersion wavelength | nm | 1300-1324 | ≧1302, ≤1322 |

---- | ---- | ≧ 1295, ≤1320 |

|

| Zero dispresion slope | nm | ≤0.092 | ≤0.091 | ---- | ---- | ---- | |

| PMD Maximum Individual Fibr | ≤0.2 | ≤0.2 | ---- | ---- | ≤0.11 | ||

| PMD Design Link Value | Ps(nm2*k m) |

≤0.12 | ≤0.08 | ---- | ---- | ---- | |

| Fibre cutoff wavelength λc | nm | ≧ 1180, ≤1330 |

≧1180, ≤1330 |

---- | ---- | ---- | |

| Cable sutoff wavelength λcc |

nm | ≤1260 | ≤1260 | ---- | ---- | ---- | |

| MFD | 1310nm | um | 9.2±0.4 | 9.2±0.4 | ---- | ---- | ---- |

| 1550nm | um | 10.4±0.8 | 10.4±0.8 | ---- | ---- | ---- | |

| Numerical Aperture(NA) |

---- | ---- | 0.200±0.015 | 0.275±0. 015 |

0.200±0 .015 |

||

| Step(mean of bidirectional measurement) |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |

| Irregularities over fiber length and point |

dB | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.10 | |